Introduction

Electronic assemblies are often requested to function in critical service environments.

They are submitted to extreme moisture and temperature conditions and sometimes they are also prone to chemical exposure of corrosive agents which could be responsible of severe failures.

These conditions are due to atmosphere, to fluxes residues employed during assembly processes, to packaging materials, vulcanized rubbers, vapor or gases emissions containing Sulphur such as petrol.

In this paper a failure related to a motorcycle headlights will be reported.

Preventlab Failure Analyses

Motorcycle headlight failure

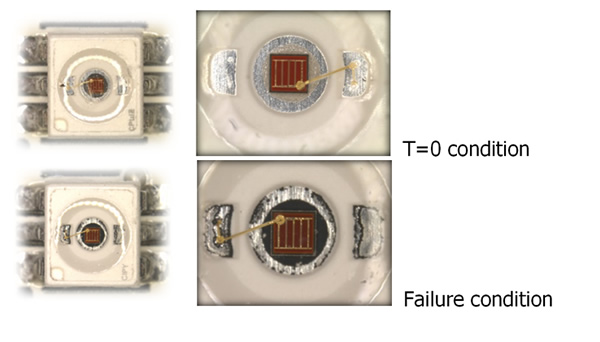

LED device inside the motorcycle headlight

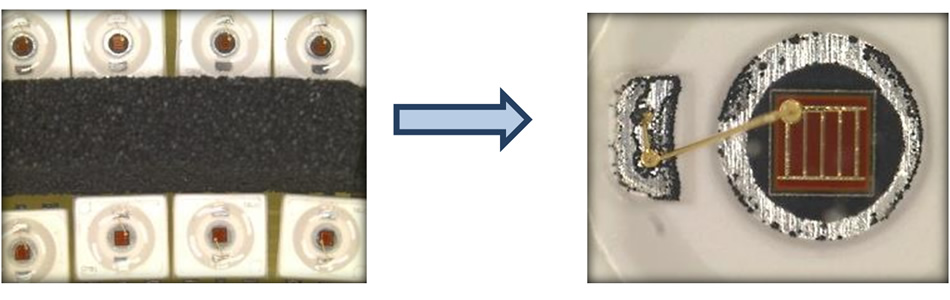

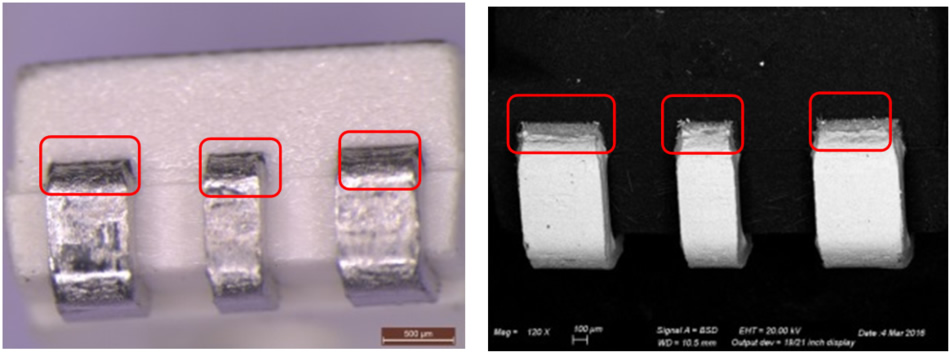

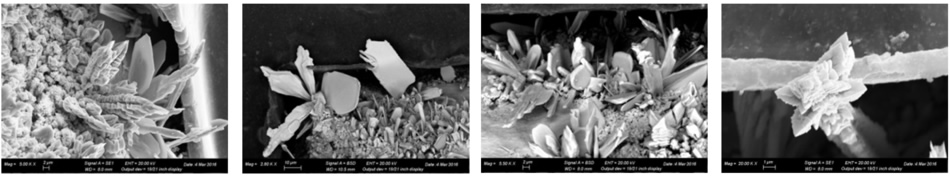

Defect reproduction in laboratory: TEST @ 60°C for 144 hrs of new LEDs near a sealing sponge

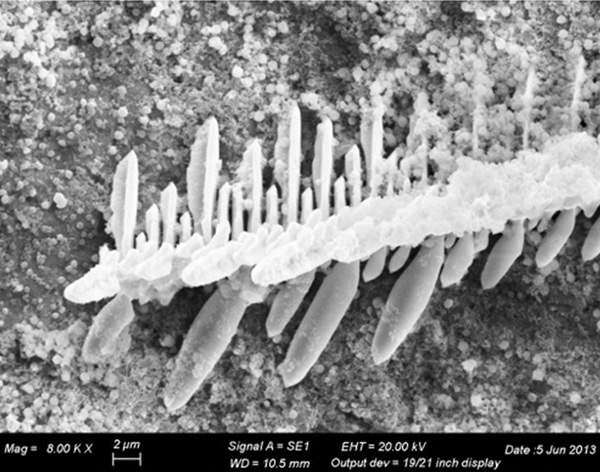

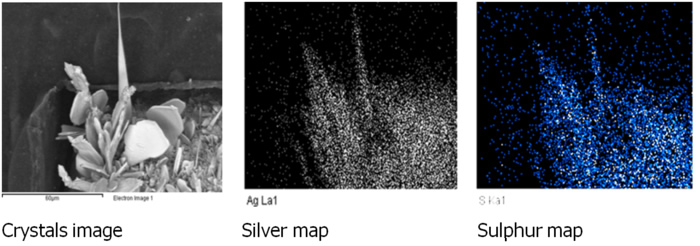

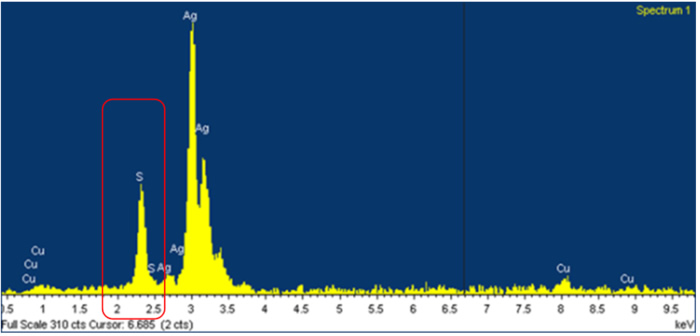

Crystal growth analysis in laboratory: optical and scanning electron microscopy

Sulphur coming from sealing sponge, under service environment conditions, volatilizes and reacts with Silver LED surfaces causing the motorcycle headlight failure.