Because of the diversity of materials available and the wide range of applications, the concept of an “ideal laminate” has become not so clear.

A material ideal for a high temperature application may be impractical in a microwave or high speed digital design, for instance.

As a result, while we can list properties that are potentially important, each design team needs to establish a prioritization among them because no one material will have the optimal value for all the properties which might be considered important

KEY ELEMENTS IN THE MATERIAL CHOICE

- Glass Transition Temperature (Tg):

The glass transition is the reversible transition in amorphous materials (or in amorphous regions within semi-crystalline materials) from a hard and relatively brittle “glassy” state into a molten or rubber-like state, as the temperature is increased.

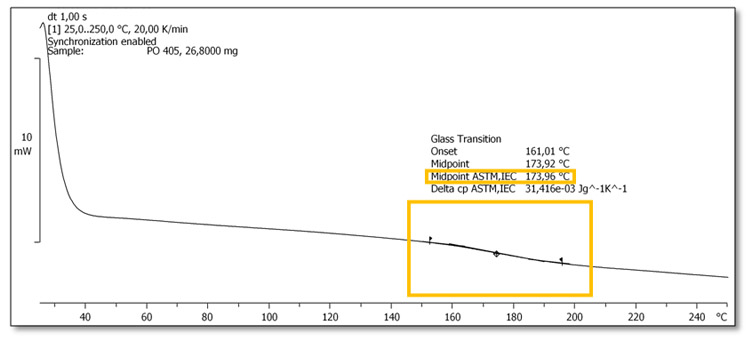

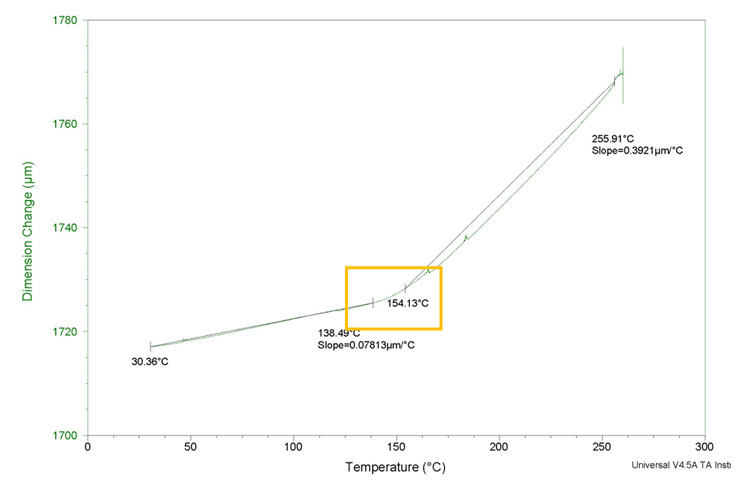

The glass-transition temperature T of a material characterizes the range of temperatures over which this glass transition occurs. It is always lower than the melting temperature, Tm, of the crystalline state of the material, if exists. This transition temperature could be determined by instrumental analysis called DSC or TMA.

The first one is regulated by IPC-TM-650 2.4.25 and the other one by IPC-TM-650 2.4.25.

For DSC method, samples are subjected to a temperature scan of 25°C to 220°C at a ramp rate of 20°C/min, and Tg was identified as the midpoint of step transition in the DSC measurement plot.

TMA uses a mechanical approach for measuring Tg. A sensitive probe measures the expansion of the test specimen when heated. Polymers typically expand as temperature is increased. From the expansion curve, a CTE can be calculated over a temperature range. If a material goes through a Tg during a TMA test, the curve shape changes significantly and Tg can be calculated by using an onset technique.

Since glass transition temperature or Tg is the temperature at which the temperature coefficient of expansion makes a significant change from a low value to a much higher value, it corresponds to a phase change in the resin system. Notice that the temperature coefficient of expansion at low temperatures is close to that of copper and glass, the two reinforcements in the X and Y directions of a PCB. When the temperature of the composite material system in a PCB exceeds its Tg, the resin part of the package begins to expand at a much more rapid rate than either the copper or the glass.

Since the resin cannot expand in either the X or Y directions, virtually all of the volume growth takes place in the Z-axis. The vias and other plated through holes are oriented in the Z-axis and are placed under stress as soldering takes place. The combination of thicker PCBs and multiple soldering operations can produce failed PCBs even before they complete the manufacturing process. Care must be exercised in choosing the proper Tg material for each application.